ATC-2018 Cutting-Stripping-Twisting-Tinning And Crimping Machine

Product Details:

- Voltage 200 Volt (v)

- Application Industrial

- Condition New

- Wire Material Steel

- Drawing Material Wire

- Click to view more

X

ATC-2018 Cutting-Stripping-Twisting-Tinning And Crimping Machine Price And Quantity

- 10 Unit

ATC-2018 Cutting-Stripping-Twisting-Tinning And Crimping Machine Product Specifications

- 200 Volt (v)

- New

- Industrial

- Steel

- Wire

ATC-2018 Cutting-Stripping-Twisting-Tinning And Crimping Machine Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

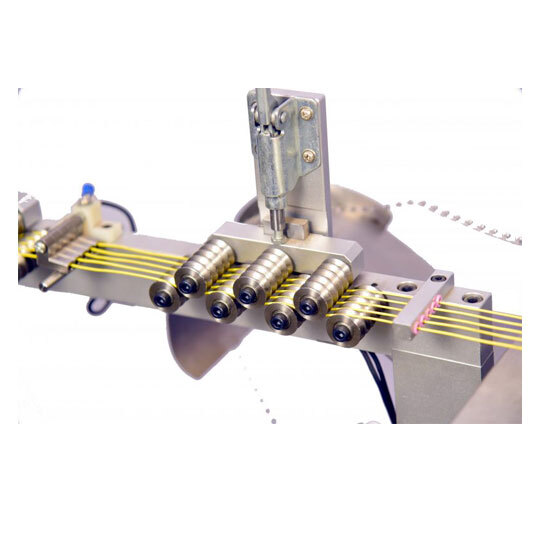

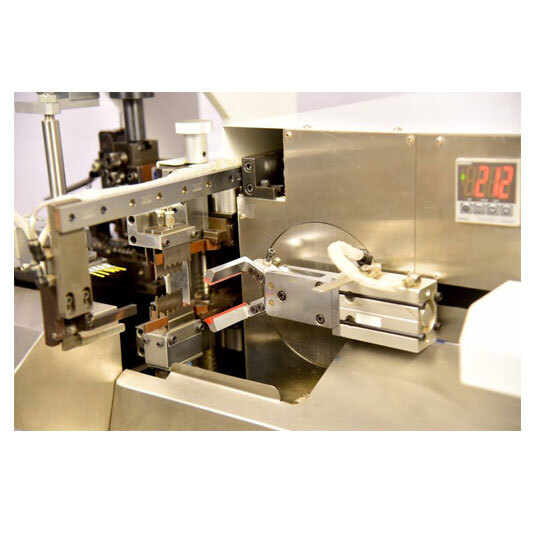

Experience a triumphant leap in industrial wire processing with the ATC-2018 Cutting-Stripping-Twisting-Tinning and Crimping Machine. Order this wondrous, top-rated solution crafted from premium steel for astounding durability. Designed for efficiency, it operates at a reduced voltage of 200 Volts, optimizing both safety and power efficiency. As a leading exporter, manufacturer, and supplier from India, we offer this new, state-of-the-art machine for precise wire drawing applications. Elevate your operations and witness enhanced productivity and consistent results with the ATC-2018 machineengineered for industrial triumphs.

Advanced Surface Application and Extraordinary Features

The ATC-2018 Cutting-Stripping-Twisting-Tinning and Crimping Machine is ideal for intricate wire surface applications in demanding industrial environments. Its extra features include automatic adjustments, rapid processing cycles, and multi-stage output that cater effortlessly to complex requirements. Designed primarily for manufacturing sites and wire production facilities, this machine guarantees seamless integration and minimal downtime, making it a truly astounding asset for industrial operations.

Stock Ready Supply, Packaging, and Delivery Features

With stock ready for immediate shipment, the ATC-2018 Machine is available at the lowest price for bulk orders. Packaging is robust and secure, ensuring safe delivery and drop-off at your chosen location. Orders are dispatched efficiently from our primary FOB port in India, enabling timely distribution to domestic and international sites. Choose streamlined logistics and reliable supply with our comprehensive export services, ensuring you never miss a production deadline.

Advanced Surface Application and Extraordinary Features

The ATC-2018 Cutting-Stripping-Twisting-Tinning and Crimping Machine is ideal for intricate wire surface applications in demanding industrial environments. Its extra features include automatic adjustments, rapid processing cycles, and multi-stage output that cater effortlessly to complex requirements. Designed primarily for manufacturing sites and wire production facilities, this machine guarantees seamless integration and minimal downtime, making it a truly astounding asset for industrial operations.

Stock Ready Supply, Packaging, and Delivery Features

With stock ready for immediate shipment, the ATC-2018 Machine is available at the lowest price for bulk orders. Packaging is robust and secure, ensuring safe delivery and drop-off at your chosen location. Orders are dispatched efficiently from our primary FOB port in India, enabling timely distribution to domestic and international sites. Choose streamlined logistics and reliable supply with our comprehensive export services, ensuring you never miss a production deadline.

FAQs of ATC-2018 Cutting-Stripping-Twisting-Tinning And Crimping Machine:

Q: How does the ATC-2018 machine improve industrial wire processing?

A: The ATC-2018 automates cutting, stripping, twisting, tinning, and crimping processes, reducing manual effort and improving output consistency, speed, and overall productivity in wire preparation tasks.Q: What materials and wire types can the ATC-2018 process?

A: The machine is specifically designed for use with steel wire and similar materials, handling various industrial wire gauges and ensuring precision with every operation.Q: Where is the ATC-2018 typically installed?

A: This machine is best suited for wire manufacturing plants, production lines, and industrial settings where high-volume wire processing is needed.Q: What are the extra features of the ATC-2018 that set it apart?

A: Key features include automatic adjustment, rapid multi-stage processing, and compatibility with diverse wire materials, making it adaptable and efficient for complex requirements.Q: When can I expect delivery after I place my order?

A: With stock ready and efficient logistics, orders are typically processed and shipped promptly from the FOB port in India, reducing wait time and ensuring swift drop-off.Q: What is the process for packaging and delivering the machine?

A: Each ATC-2018 machine is securely packaged for safe transit and delivered to your designated site by our trusted courier partners, maintaining the machine in pristine condition upon arrival.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese